runner stick

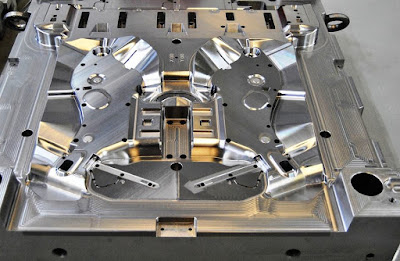

What is the runner stick runner stick refer to a phenomenon in which the runner of the molded article fails to separate from the mold. If the holding pressure is applied for a long time ,so that the size of the runner is increased, or the runner path portion of the mold is scratched or undercut, resistance is generated, so that the runner cannot be peeled off when the mold is opened. Reasons for the runner sticking Insufficient solidification of runner When the main runner is not fully cured, the shrinkage is small at this moment, and the runner is close stick to the mold, and the strength is also low. Therefore, if the runner is to be ejected at this time, it will be very easy to break. In this way, the runner will remain on the channel. Resin temperature, mold temperature, and cycle (cooling time) have an effect on the solidification of the main flow. Excessive pressure holding The main runner channel is separated from the barrel nozzle directl...